ANSI B18.2.3.7M 1979(R 89,95)

IFI NOTES:

1. ANSI B

2. ISO 7412-1984 Hexagon Bolts for High-Strength Structural Bolting With Large Width Across Flats (Short Thread Length)- Product Grade C-Property Classes 8.8 and 10.9 is functionally interchangeable with products to this standard. The ANSI standard provides longer grip lengths and body lengths as standard, but it does not include the M12 as standard. The longer thread lengths of ISO 7411 do not facilitate interchangeability. The undersizing of bolt threads allowed within these two standards is a practice not acceptable in

3. Government requirements covering standard item selection, part numbers, quality assurance, and packaging have been omitted in this reprint of B

GENERAL DATA

1. Scope

1.1 This standard covers the complete general and dimensional data for metric heavy hex structural bolts recognized as American National Standard.

1.2 The inclusion of dimensional data in this standard is not intended to imply that all of the sizes in conjunction with the various options described herein are stock production items. Consumers are requested to consult with manufacturers concerning lists of stock production heavy hex structural bolts.

2. Comparison With ISO Standards

2.1 Heavy hex structural bolts as presented in this standard have been coordinated, to the extent possible, with a draft ISO proposed standard. The dimensional differences between this ANSI standard and the ISO proposal are few, relatively minor, and none will affect the functional interchangeability of bolts manufactured to the requirements of either.

The following functional characteristics of bolts are in agreement between this ANSI standard and the ISO proposal:

Diameters ad thread pitches

Body diameters

Widths across flats

Bearing surface diameters

Head heights

Thread lengths(see Para.15)

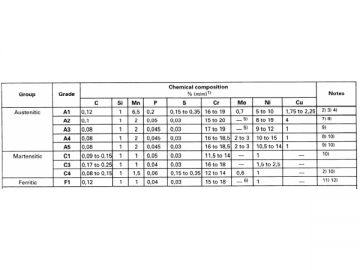

Thread dimensions

Nominal lengths

2.2 There will be two ISO standards for heavy hex structural bolts, with the only difference between them being length of thread. This ANSI standard is essentially identical to the proposed ISO standard for bolts with the shorter thread lengths.

2.3 Letter symbols designating dimensional characteristics are in accord with those used in ISO standards, except capitals have been used for data processing convenience instead of lower case letters used in ISO standards.

3. Dimensions

3.1 All dimensions in this standard are in millimeters, unless stated otherwise.

3.2 Symbols specifying geometric characteristics are in accord with American National Standard, Dimensioning and Tolerancing, ANSIY14.5-1973.

4. Top of Head. The top of head shall be full form and chamfered or rounded. The diameter of the chamfer circle of the start of rounding shall be equal to the maximum width across flats within a tolerance of minus 15 percent.

5. Head Height. The head height is the distance, as measured parallel to the axis of the bolt, from the top of the head to the underhead bearing surface.

6. Wrenching Height. The wrenching height is the distance, measured at a corner of the hex, from the plane of the bearing surface to the last plane of full formed hex, i.e., the plane closest to the top of head at which the width across corners of the hex is within its specified limits.

7. Corner Fill. The rounding due to lack of fill at the six corners of the head shall be reasonably uniform.

8. True Position of Head. The axis of the hex head shall be located at true position with respect to the axis of the bolt (determined over a distance under the head equal to one bolt diameter) within a tolerance zone of diameter equal to 6 percent of the specified maximum width across flats.

9. Bearing Surface. The bearing surface shall be flat and washer faced. However, a die seam across the bearing face shall be permissible. Diameter of bearing surface shall not exceed the width across flats nor be less than the specified minimum washer face diameter. For referee purposes, measurement of bearing surface diameter shall be taken at mid-thickness of the washer face. The plane of the bearing surface shall be perpendicular to the axis of the body within the total runout specified in Table 1. The measurement of bearing face runout shall be made as close to the periphery of the washer face as possible while the bolt is held in a collet or other gripping device at a distance equal to one bolt diameter from the underside of the head. Angularity measurement shall be taken at a location to avoid interference from a die seam.

10. Body Diameter

10.1 Bolts shall be furnished with a full diameter body within the limits specified in Table 1.

10.2 There may be a reasonable swell, fin or die seam on the body adjacent to the underside of head not to exceed the nominal bolt diameter by the following:

NOTES:

1. Lg is grip gaging length; Ls is body length.

2. Bolts with lengths above the heavy solid line are threaded full length.

3. For bolts with longer lengths, Lg and Ls values shall be computed from formulas as given in Note 15 General Data.

11. Fillet. The fillet at junction of head and shank shall be a smooth concave curve within an envelope of R minimum, and a smooth multiradius curve tangent to the underside of head at a point no greater than one-half of Da maximum from the axis of the bolt and tangent to the shank of the bolt at a distance no greater than F maximum from the underside of head.

12. Length. Recommended lengths of bolts are given in Table 2. The length of the bolt shall be measured parallel to the axis of the bolt from the underhead bearing surface to the extreme end of the shank. Length tolerances shall be as specified in Table 3.

13. Points. The end of the bolt shall be chamfered from a diameter equal to or slightly less than the thread root diameter to produce a length of chamfer of incomplete thread within the limits for Z specified in Table 4. The end of the bolt shall be reasonably square with the axis of bolt, and where pointed blanks are used, the slight rim or cup resulting form roll threading shall be permissible. At the manufacturer’s option, the end of the bolt may have a rounded point of radius V as specified in Table 4.

14. Straightness. Shanks of bolts shall be straight within a maximum camber of

15. Thread Length

a) The length of thread on bolts shall be controlled by the maximum grip gaging length (Lg) and the minimum body length ( Ls ) as set forth in 15.2 thtu 15.5.

b) Grip gaging length, Lg max, is the distance measured parallel to the axis of the bolt, from the underhead bearing surface to the face of a noncounterbored or noncountersunk standard GO thread ring gage assembled by hand as far as the thread will permit. For standard diameter-length combinations of bolts the values for Lg max are specified in Table 2. For diameter-length combinations not listed in Table 2, the maximum grip gaging length, as calculated and rounded to one decimal place, shall be equal to the nominal bolt length, L, minus the basic thread length, B, as specified in Table 1 (Lg max =L-B). Lg max shall be used as a criterion for inspection.

c) Body length, Ls min, is the distance, measured parallel to the axis of the bolt, from the underhead bearing surface to the last scratch of thread or the top of the extrusion angle, whichever is closest to the head. For standard diameter-length combinations of bolts the values of Ls min are given in Table 2. For diameter-length combinations not listed in Table 2, the minimum body length, as calculated and rounded to one decimal place, is equal to the maximum grip gaging length (as computed ) minus the maximum transition thread length as given in Table 1 (Ls min=Lg max-X max). Ls min shall be used as a criterion for inspection. Bolts of nominal lengths which have a calculated Ls min value equal to or less than the length of 2.5 times the thread pitch shall be threaded full length. Bolts which are threaded full length shall have a minimum body length under the head equal to F as specified in Table 1.

d) Basic thread length, B, as specified in Table 1 is a reference dimension intended for calculation purposes only, and is the distance, measured parallel to the axis of the bolt, from the extreme end of the bolt to the last complete (full form) thread.

e) Transition thread length, X max, as specified in Table 1 is a reference dimension intended for calculation purposes only. It includes the length of incomplete threads and tolerances on grip gaging length and body length. The transition from full thread to incomplete thread shall be smooth and uniform. The major diameter of the incomplete threads shall not exceed the actual major diameter of the complete (full form) threads.

16. Thread Series. Threads shall be metric coarse thread series conforming to dimensions for general purpose external threads given in ASME B1.13, page A-20. The Class

17. Thread Acceptability. Unless otherwise specified by the purchaser, gaging for screw thread dimensional acceptability shall be in accordance with Gaging System 21 as specified in ASME B

(IFI Note: Para. 17 is not included in ANSI B

18. Material and Mechanical Properties. Chemical composition and mechanical requirements of steel bolts shall conform to ASTMA

19. Finish. Unless otherwise specified, screws and bolts shall be supplied with a natural ( as processed ) finish, unplated or uncoated.

20. Identification Symbols. Steel bolts shall be marked with the grade identification symbols and with the manufacturer’s identification symbol. Minimum height of property class symbols shall be

21. Options. Options, where specified, shall be at the discretion of the manufacturer unless otherwise agreed upon by the manufacturer and the purchaser.

22. Terminology. For definition of terms relating to fasteners or component features thereof used in this standard, refer to American National Standard, Glossary of Terms for Mechanical Fasteners, ASME B18.12. See page K-37.

23. Workmanship. Bolts shall not contain an excess of surface imperfections which might affect their serviceability, such as burrs, seams, laps, loose scale and other irregularities.

24. Clearance Holes. The recommended sizes of clearance holes in material to be assembled using heavy hex structural bolts are the normal series given in IFI-527, page K-7.

25. Designation

25.1 Heavy hex structural bolts shall be designated by the following data preferably in the sequence shown: product name, nominal diameter and thread pitch, nominal length, steel property class, and protective coating, if required.

Note

It is common practice in ISO standards to omit thread pitch from the product size designation when screw threads are the metric coarse thread series, e.g., M20 is M20×2.5.

Examples:

Heavy hex structural bolt, M22×2.5×160, ASTM A

Heavy hex structural bolt, M24×3×80, ASTM A

26. Inspection and Quality Assurance. Unless otherwise specified by the purchaser in the original inquiry and purchase order, acceptability shall be based on conformance with the requirements specified in ANSI B

(IFI Note: Para.26 is not included in ANSI B

27. Referenced Standards. Titles and source of availability of all documents referenced in this standard are given on page K-41.